Description

The materials filled in the high pressure cylinder are forced by the high hardness plunger rod to pass through the specially designed diamond inlaid micro aperture channel in the homogenization chamber with extremely high pressure (up to 300Mpa) to form a supersonic micro jet, which breaks the material particles by using the strong shearing and impact effects between high-speed jets, thus producing a fully mixed, uniform and finer product, which can significantly improve the emulsification, solubility, stability and transparency of materials. The particle size is refined and the distribution is narrowed to meet the high-end homogenization needs of pharmaceutical, biotechnology, cosmetics, food, graphene and other industries.

Specification

| Feeding particle size | <100um |

| Processing speed | 10L/H |

| Maximum pressure | 2600bar |

| Minimum processing capacity | 15ml |

| Residual quantity | <0.13ml |

| Maximum feed temperature | 90℃ |

| Maximum sterilization temperature | 130℃ |

| Temperature control | The discharge temperature can be controlled within 10 degrees, ensuring higher biological activity. |

| Pressure regulation method | Manual |

| Working environment temperature | Indoor -10~50℃ |

| Power | AC380V 1.5KW |

| Dimension(L*W*H) | 510*385*490 |

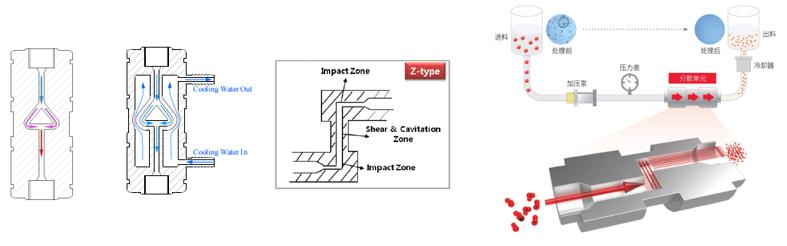

Working principle

After the material flows through the one-way valve, it is pressurized in the high pressure chamber pump. Through the micron level channels and nozzles, it impacts at subsonic speed (Z-type impact emulsion chamber, Y-type impact). At the same time, through strong cavitation and shear effects, it can obtain a small and uniform particle size distribution.

While ensuring safety, the unique cavity structure can make the homogenization pressure reach to 3000 bar, effectively solving the nanometer dispersion of particles, and at the same time, it can also circulate homogenization.

Experimental effect of lecithin encapsulated vitamin C

Why Choose Us

PTH-10 microfluidizer homogenizer offers numerous advantages that make it a popular tool in the liquid processing industry. Its excellent homogenization effect, easy operation, energy-saving features and wide application make it stand out in the homogenization field.