Description

The PT-10 high pressure homogenizer has a stable structure, small occupation and user-friendly operation, making it suitable for a variety of laboratory environments. The high pressure vessel is made of corrosion-resistant materials and can withstand high-pressure working conditions to ensure the safety and reliability of the equipment. In addition, the intelligent control system enables precise parameter adjustment and real-time monitoring, ensuring the accuracy and controllability of the homogenization process.

Specification

| Feeding particle size | <300μm |

| Processing speed | 5-10 L/H |

| Maximum pressure | 1750bar |

| Minimum processing capacity | 15ml |

| Maximum feed temperature | 90℃ |

| Maximum sterilization temperature | 130℃ |

| Temperature control | The discharge temperature can be controlled within 10 degrees, ensuring higher biological activity. |

| Pressure regulation method | Manual |

| Working environment temperature | Indoor -10~50℃ |

| Power | AC220V 1.5KW |

| Dimension(L*W*H) | 765.5*483.5*430mm |

Working Principle

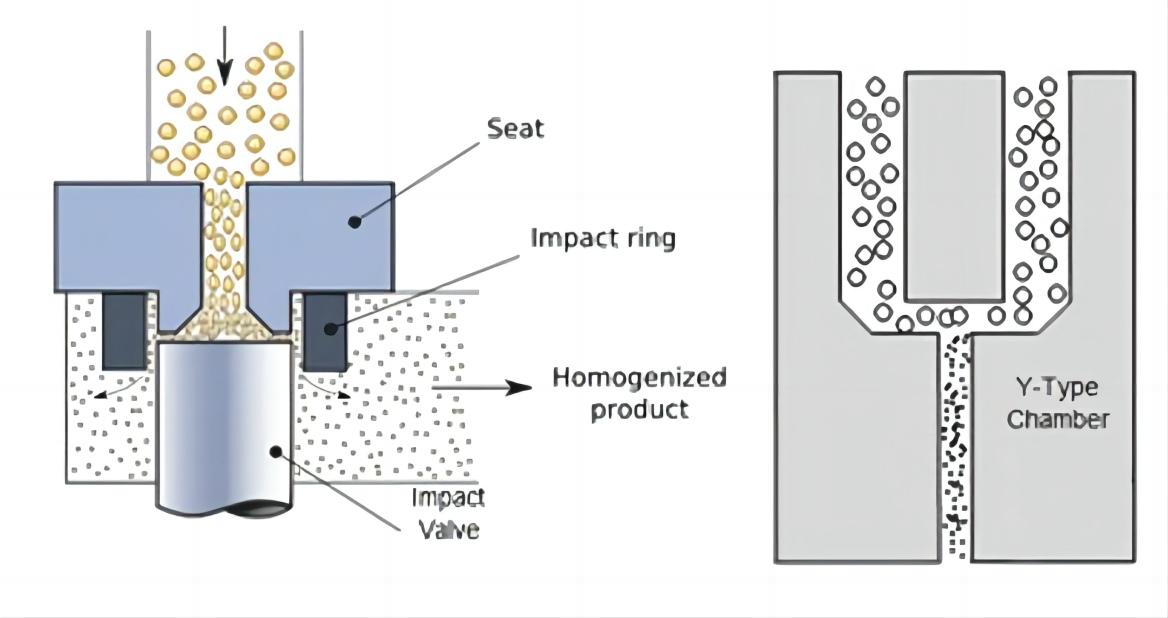

The high pressure homogenizer has one or several reciprocating plungers. Under the action of the plungers, the materials enter the valve group with adjustable pressure. After passing through the flow limiting gap (working area) of a specific width, the materials that lose pressure instantaneously are ejected at a very high flow rate (1000-1500 m/s) and collide with the impact ring of one of the impact valve components, producing three effects: cavitation effect, impact effect and shear effect. After these three effects, the particle size of the material can be uniformly refined to less than 100nm, and the crushing rate is greater than 99%!

Why Choose Us

1. Professional system team, strong technical support and service.

2. Exquisite appearance and ergonomic design.

3. Can test a variety of small samples.

4. The incomparable particle size reduction efficiency and narrower particle size distribution are applicable to a variety of nanometer homogeneous fields.