Description

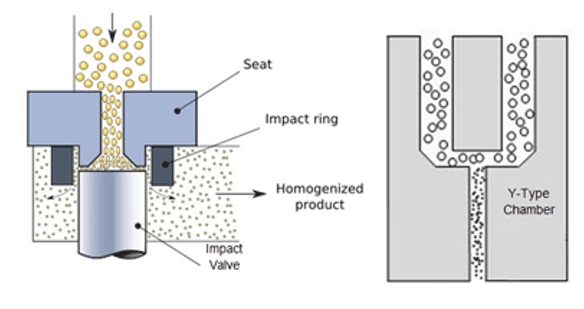

At the heart of the PT-20 high pressure homogenizer lies its reciprocating plungers. These plungers, driven by a powerful motor, enable the homogenizer to exert adjustable pressure on the materials being processed. As the materials pass through the flow limiting gap, which has a specific width, the pressure is suddenly released, resulting in a high flow rate of 1000-1500 m/s. This rapid flow rate, in combination with the impact ring of the valve components, generates three effects: cavitation effect, impact effect and shear effect.

Specification

| Feeding particle size | <300μm |

| Processing speed | 10-20 L/H |

| Maximum pressure | 1800bar |

| Minimum processing capacity | 25ML |

| Maximum feed temperature | 90℃ |

| Maximum sterilization temperature | 130℃ |

| Temperature control | The discharge temperature can be controlled within 10 degrees, ensuring higher biological activity. |

| Pressure regulation method | Manual |

| Working environment temperature | Indoor -10~50℃ |

| Power | AC380V 2.2KW |

| Dimension(L*W*H) | 739*523*420 |

Working Principle

Cavitation effect: one of the key mechanisms at play in the PT-20 High Pressure Homogenizer. As the materials pass through the flow limiting gap, the sudden pressure drop induces the formation and collapse of minute bubbles within the liquid. This cavitation effect leads to the creation of highly localized high temperatures and pressures, resulting in enhanced emulsification and dispersion. This effect ensures uniform particle size distribution and improves the stability and quality of the emulsified products.

Impact effect: another vital aspect of the PT-20 High Pressure Homogenizer. As the materials collide with the impact ring, the intense force generated causes the particles to break down and undergo further refinement. This impact effect is particularly beneficial for homogenizing and micronizing substances that are difficult to process using conventional methods. By subjecting the materials to high-velocity impacts, the homogenizer facilitates the production of finer and more uniform particles.

Shear effect: as the materials flow through the narrow flow limiting gap, they experience significant shear forces due to the intense velocity gradient. This shear effect contributes to the reduction of particle size and the disruption of any agglomerates or aggregates present in the materials. By subjecting the materials to shear forces, the homogenizer ensures a consistent and homogenous final product.

Why Choose Us

The PT-20 High Pressure Homogenizer with its state-of-the-art design and innovative technological features, this homogenizer offers unparalleled precision, efficiency, and quality. Whether you are working in the pharmaceutical, cosmetic, or food industry, the PT-20 laboratory homogenizer machine is an indispensable tool for achieving superior emulsification and dispersion results.

Upgrade your experimental processes today with the PT-20 high pressure homogenizer and experience the future of emulsification technology.