Description

This lab homogenizer can widely used in major scientific research institutions and pharmaceutical enterprises.

Application field include:

Biological industry (protein drugs, testing reagents, enzyme engineering, human vaccines, veterinary vaccines.)

Pharmaceutical industry (fat emulsion, liposomes, nanoparticles, Microspheres.)

Food industry (beverages, milk, food additives.)

Chemical industry (new energy batteries, nano cellulose, coating and papermaking, polymer materials.)

Specification

| Feeding particle size | <300μm |

| Processing speed | 10-20 L/H |

| Maximum pressure | 1800bar |

| Minimum processing capacity | 25ML |

| Maximum feed temperature | 90℃ |

| Maximum sterilization temperature | 130℃ |

| Temperature control | The discharge temperature can be controlled within 10 degrees, ensuring higher biological activity. |

| Pressure regulation method | Manual |

| Working environment temperature | Indoor -10~50℃ |

| Power | AC380V 2.2KW |

| Dimension(L*W*H) | 739*523*420 |

Working principle

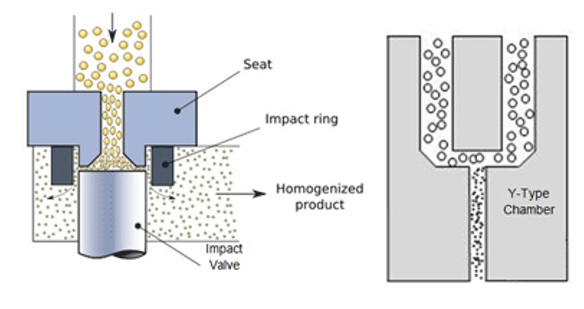

The homogenizer machine has one or several reciprocating plungers. Under the action of the plungers, the materials enter the valve group with adjustable pressure. After passing through the flow limiting gap (working area) of a specific width, the materials that lose pressure instantaneously are ejected at a very high flow rate (1000-1500 m/s) and collide with the impact ring of one of the impact valve components, producing three effects: Cavitation effect, Impact effect and Shear effect.

After these three effects, the particle size of the material can be uniformly refined to less than 100nm, and the crushing rate is greater than 99%!

Why Choose Us

The homogenization effect of our PT-20 laboratory homogenizer can uniformly refine the material particle size to below 100nm, and the crushing rate is greater than 99%.